Learn through the super-clean Baeldung Pro experience:

>> Membership and Baeldung Pro.

No ads, dark-mode and 6 months free of IntelliJ Idea Ultimate to start with.

Last updated: April 14, 2024

Industry 4.0 represents the fourth industrial revolution, where digital, physical, and biological technologies converge. It promises to transform the manufacturing landscape through automation, data exchange, and connectivity.

In this article, we’ll explore Industry 4.0, including its components, benefits, challenges, and impact on the global manufacturing sector.

While foundational to our current economic structures, traditional manufacturing struggles with several core issues—rigidity in production lines, inefficiency in resource use, and limitations in data utilization. Industry 4.0 revolutionizes the manufacturing landscape using modern and advanced technologies like the Internet of Things (IoT), artificial intelligence (AI), and big data to create smart factories. These innovations are transforming industrial operations, making them automated and interconnected, optimizing production efficiency.

Interest in Industry 4.0 is driven by its potential to enhance how products are designed, produced, and distributed. Manufacturers are motivated by the possibility of reducing their operational costs and improving product quality. The transition to Industry 4.0 allows production processes to be swiftly adjusted in response to changing market demands, providing manufacturers with a competitive edge over their competitors. When businesses use Industry 4.0 tools, they can collect, analyze, and understand large amounts of data in real-time.

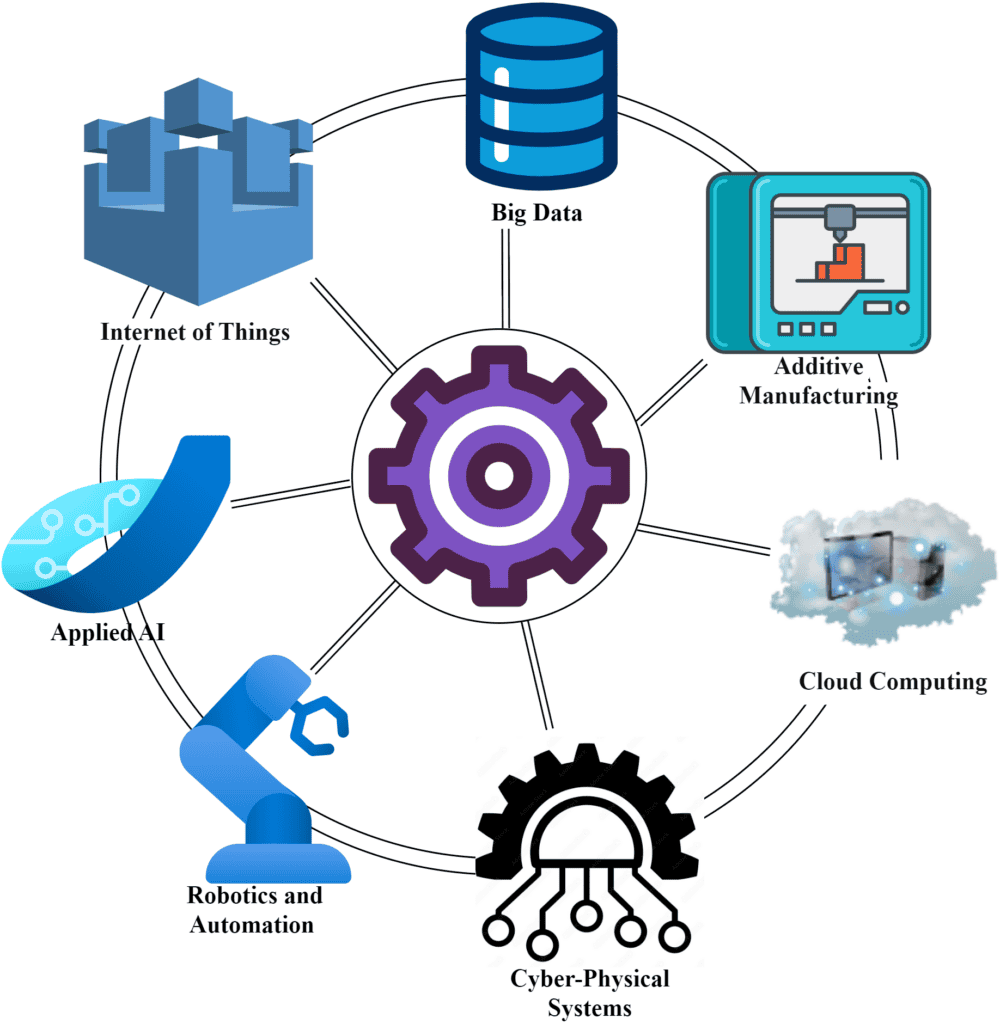

Industry 4.0 is based on several key technologies that work together. At the core of this ecosystem are cyber-physical systems (CPS), which connect the physical and digital worlds. CPS are intelligent systems that monitor and control physical processes using sensors and actuators. They collect real-time data, analyze it, and use it to drive intelligent actions back into the physical world. This ongoing loop of real-time information significantly enhances our manufacturing processes’ automation, efficiency, and flexibility.

In Industry 4.0, we use a suite of transformative technologies. We use cloud computing to handle and store the massive amount of data generated by the IOT devices. We analyze this data using big data analytics systems, which rely on AI to execute complex tasks. In additive manufacturing or 3D printing, we use AI to produce customized solutions with great accuracy and efficiency. Moreover, we can perform precise and complex tasks to improve our manufacturing capabilities using advanced robotics empowered by AI.

All these different technologies work together to increase efficiency and connectivity:

Together, these technologies define the backbone of Industry 4.0, driving more innovative, faster, and more adaptable manufacturing processes.

Let’s consider a smart factory implementing these Industry 4.0 technologies. In this setting, we can use IoT devices to continuously monitor production lines to track efficiency and predict potential failures before they occur. We can also use AI algorithms to analyze the data and optimize machine scheduling and maintenance routines to reduce downtime.

Meanwhile, we can use cloud and edge computing to ensure data is accessible in real-time. In additive manufacturing, we can quickly switch between designs with minimal downtime, meeting customer demands for customization. Similarly, we can use robots with advanced sensors and AI to handle complex assembly tasks and enhance productivity.

This approach enhances efficiency and drives us towards a more flexible and responsive future, demonstrating the transformative potential of industry 4.0 technologies.

Let’s check out the main benefits and challenges of Industry 4.0:

| Benefits | Challenges |

|---|---|

| Enhanced productivity and efficiency | Increased risk of cybersecurity threats |

| Customized products with shorter lead times | High initial costs of technology implementation |

| Improved sustainability and energy savings | Skills gap requiring workforce training |

Our adoption of Industry 4.0 technologies significantly improves productivity and operational efficiency. We can offer customized products with shorter lead times. Implementing sustainable practices becomes simpler, leading to energy savings and a reduced environmental impact. Moreover, our supply chains can become more resilient and adaptable to changes:

However, transitioning to Industry 4.0 is not without its challenges. With more connectivity, the risk of cybersecurity threats increases. The initial cost of implementing these technologies may be too high for some. Additionally, there’s a skills gap, as our workforce needs training in these new technologies. We’ll need to address these challenges to embrace the potential of Industry 4.0 fully.

As we look to the future, Industry 4.0 continues to evolve. Integrating digital twins, augmented reality, and blockchain technology into manufacturing processes suggests endless opportunities. Digital twins create virtual replicas of physical devices, allowing us to simulate and optimize manufacturing processes before implementation. Augmented reality provides us with real-time and enhanced graphical information, improving our decision-making and training. Meanwhile, we can use blockchain technology to track the life cycle of products and materials securely and transparently.

We can’t ignore the critical roles that policy, education, and investment play in supporting this growth. Effective policies should ensure that technological integration adheres to sustainability and safety standards and protects intellectual property. Education equips the current and future workforce with the necessary skills to navigate the complexities of advanced technologies. Moreover, investment in research and development fuels continuous innovation and helps us bring these technologies from conception to reality.

As industries adapt to this new era, we must focus on ethical considerations and the social impact of automation and AI. We must also develop strategies that address potential job displacement and establish equal distribution of economic benefits for the entire society.

In this article, we looked into Industry 4.0, a technological revolution and a paradigm shift in manufacturing and industrial practices.

Industry 4.0 represents the fourth industrial revolution, which integrates digital technologies like IoT, AI, and robotics into manufacturing, fundamentally transforming production and operational processes.

Embracing Industry 4.0 requires a concerted effort to overcome challenges, including the need for new skills, technologies, and infrastructure. We can achieve this through investment in research and development, education and training, and infrastructure upgrades. To take advantage of Industry 4.0, we must also embrace new working methods, such as agile methodologies, open innovation, and co-creation.