Learn through the super-clean Baeldung Pro experience:

>> Membership and Baeldung Pro.

No ads, dark-mode and 6 months free of IntelliJ Idea Ultimate to start with.

Last updated: March 10, 2024

We often find the expression digital twins when reading about virtual representations of places. But is the concept limited to places, and what is the goal of having such representation?

In this tutorial, we’ll discuss the definition of digital twins. Then, we’ll explore an example of how to create one and see the required technologies. To conclude, we’ll highlight the main advantages of digital twins and go through the implementation steps.

A digital twin is a virtual representation of a process, system, or physical object, serving as its real-time digital counterpart.

To create a digital twin, we must first know the intended goal. For example, it can be the optimization of a process to reduce costs, or we may want to simulate scenarios that would be dangerous in the real world.

We’ll present the optimization of machinery positioning in a car factory.

Why would anyone want to do this? Well, let’s say we have to physically change and rearrange the machines to test several configurations. Doing it physically, we’ll have to stop production and spend time and workforce to conduct our experiment, exposing the factory to serious liabilities to the workers if something unexpected happens. A better approach is to simulate a digital twin of the factory and test the configurations on a computer.

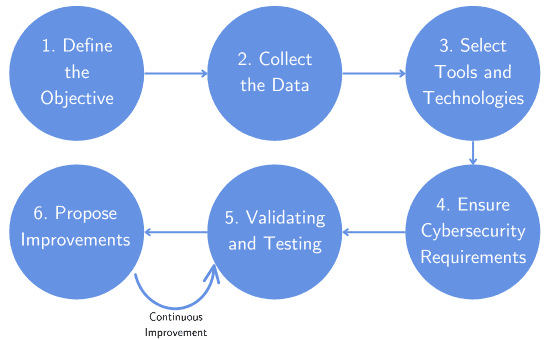

This task requires different steps. In this article, we present and discuss each of the following six steps:

But before starting to build our model, we need to collect data. We need as much information as possible about the environment and processes: the physical dimensions of the factory, the current positions of each machine, the order in which we assemble a car, etc. Besides that, we need to collect historical data. How many workers are there for each period of a day? How long does it take for an operator to move from point A to point B? Which machines require human intervention to operate properly?

Additionally, we can use sensors to measure temperature, air pollution, and vibration. Then, we can avoid exposing the workers to harmful environments for long periods. This illustrates the integration of the Internet of Things (IoT) with digital twins.

Having collected the data, it’s time to start developing the virtual model.

We must choose a software or platform that enables the representation of the factory. Companies such as Autodesk, Amazon, and Siemens have solutions specially designed for digital twins, but there are alternative options.

In our case, the software must incorporate all the data that we collected previously. So, the simulation should include the movement of each worker. Given the limitations of traditional tables and 2D drawings, a 3D representation of the whole environment is essential. It provides the stakeholders with a representation of complex structures or systems. The whole spatial configuration of the environment and dimensions are accurately represented in the virtual replica. We can also visualize our model using more sophisticated tools with augmented or virtual reality.

These tools should reflect changes that happen in the physical world in the digital twin. In this way, we’ll be sure that our model evolves with the process.

Now, we should make a brief consideration regarding information security. Since our data is transmitted to the cloud, we must meet cybersecurity requirements. This is ensured by establishing a secure structure that protects any critical information.

We should also consider that we’re processing the data on-site. That means that we don’t send the information provided by the sensors to a remote server. Instead, we compute everything in the factory. This is the exact definition of edge computing.

Now, we need to integrate the data and the model, which we do using the tools from data analytics or machine learning. We must analyze the bottlenecks of the production line. After that, we need to identify what we can change.

In our example, we might test different sequential orders for the machines, respecting the logical requirements of assembling a car. We can also test different distances between workstations. This enables us to consider the safety of the employees and time efficiency.

In the testing and validation phase, our goal is to precisely predict the outcomes of a given change. This kicks off an iterative process for the refinement of our model. With this feedback loop, we can continuously monitor and improve the performance of the factory.

Designing the digital twin version of a factory allows us to make changes efficiently. It also enables us to test adjustments without compromising the integrity of workers. We also avoid negative impacts on productivity by not shutting down the whole production line.

In this article, we defined digital twins and showed how to create one.

We can create a digital counterpart of a physical object or a process after gathering all the relevant information about our physical world. This counterpart helps us optimize any process, make decisions, and minimize risks.